The ultimate guide for radon instruments

There are many different instruments to choose from nowadays. Prices for radon instruments vary widely, and they can cost from 300 € up to 15 000 €. Basically though, ‘you get what you pay for’. This means that there is no cheap, magical instrument that will work everywhere.

Major differences in capacity and function

Generally speaking, cheaper instruments have a smaller chamber and detector, which means they have trouble measuring changes in radon levels with sufficient margin of error in time intervals of under 1–2 hours. Neither is it therefore possible to change measuring point quickly with that type of instrument. On the other hand, a more basic instrument may be absolutely fine if you want to measure daily variations, or measure radon levels during work hours. It may be fully adequate for property owners who want to keep a check on radon levels over a long period.

On the other hand, if you work in inspection or radon decontamination, for instance as a radon consultant, you should expect to invest in more expensive instruments with a larger pulsed ionisation chamber/detector, which can produce measurements with an acceptable margin of error within 15 minutes. With an instrument like this, you can also quickly move measuring points and deal with high levels of radon at penetration points. This is because the instrument constantly separates unwanted contamination of radon and its decay products from the previous measuring point. Put simply, without an instrument like this, it is impossible to perform professional radon inspections.

Always choose an instrument based on application

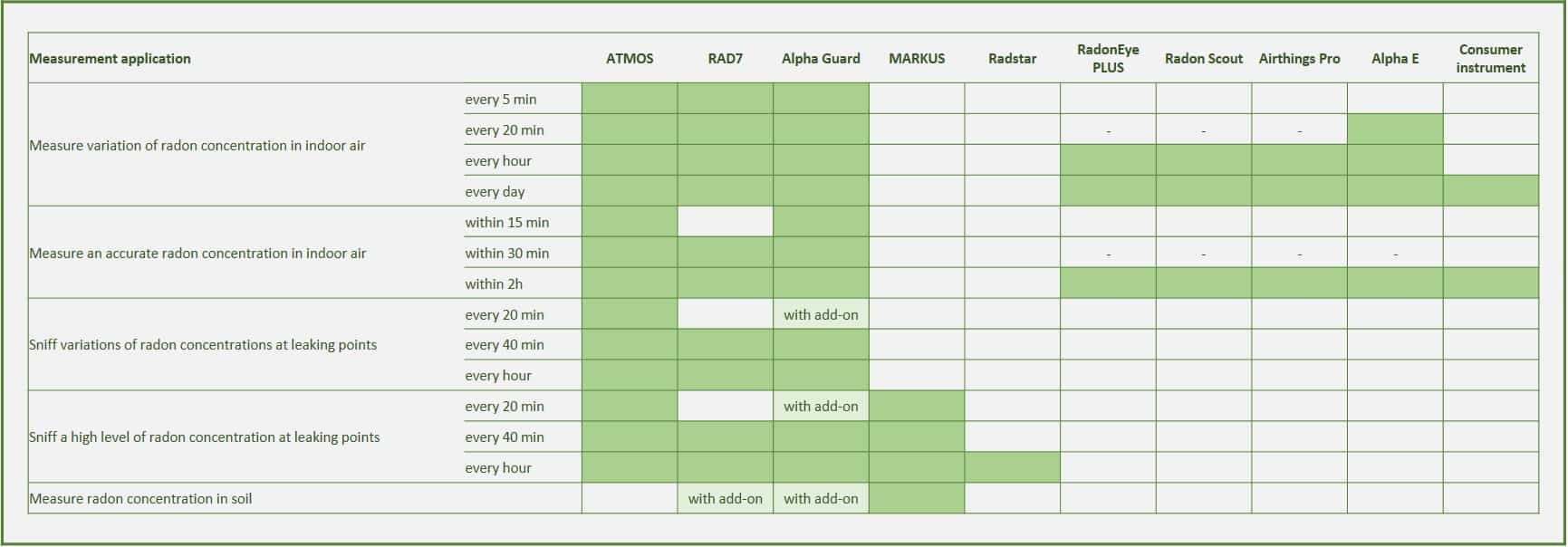

Sniffer, Logger, Grabber – radon instruments have all kinds of names. If you’re new to the radon sector it can be a bit of a jungle, but fundamentally it’s all about what the instrument will be used for. The table below lists the most common applications. If you work as a radon consultant, you will probably need a combination of different radon instruments. Property owners too may require more than one instrument. This depends mainly on how much of the measuring work you want to do yourself, and how much you want to outsource.

When you invest in an instrument, it is therefore vital to clearly define your intended application, both now and in the future. Ask yourself the following questions, for example:

- Is radon being measured indoors or in the ground?

- How often will I need to move the instrument between different measuring points?

- How often do readings need to be taken?

- How many measuring points need to be measured simultaneously?

It should be easy to read and handle measurement data

The measurement chamber and detector are the very heart of any instrument, but how the instrument communicates is just as important; i.e. how the measurement data is shown and how the software works. How can measurement data be exported? Also, which time intervals can be presented in the form of graphs. Do the measurement results indicate a margin of error? What reports can be generated?

How well the software is adapted to your way of working (on measuring radon) is hugely important to how efficient your process is once the measuring has been done. You will save a lot of time if you have software that can output the measurement report you need, rather than having to export the data and then compile your own report. So one important tip is to think about how you work today and how you want to work in the future, and find out about the software capabilities of different instruments. Before you invest in an instrument, always ask for a demonstration of the software.

Calibration is essential to precision

Calibration entails setting the instrument to a known radon source, which essentially means checking and adjusting to ensure that the radon instrument measures correctly. The instrument should initially be calibrated at the place of manufacture, and once a year thereafter. This is because measurement chambers and detectors become contaminated by the radon gas’s decay products, and consequently efficiency and energy calibration must be carried out, along with background adjustment. Most countries have some kind of requirements on this, understandably. After all, producing incorrect measurement results defeats the whole point of measuring radon in the first place. In the worst case human health may be put at risk, especially if high values have not been identified. Even so, calibration is often neglected. Some cheaper instruments are not even designed to be calibrated again after manufacture. This essentially means that you have to buy a new instrument every year to ensure accurate readings.

Therefore, always request a calibration certificate from the manufacturer. As a radon consultant, you should also always have your instruments calibrated annually. If you are a property owner engaging a radon consultant, always ask to see the latest calibration certificate for the instruments they will be using. It’s also important to check that the supplier you buy the instruments from has an organisation that can deal with calibration and any servicing requirements. Unfortunately, this cannot be taken for granted.

We hope this guide has been helpful. If you have any questions, please feel free to contact us here.

Good luck with choosing your radon instruments!